Our TSE configurator provides you with customized linear motion drives. Please contact us if you have any questions.

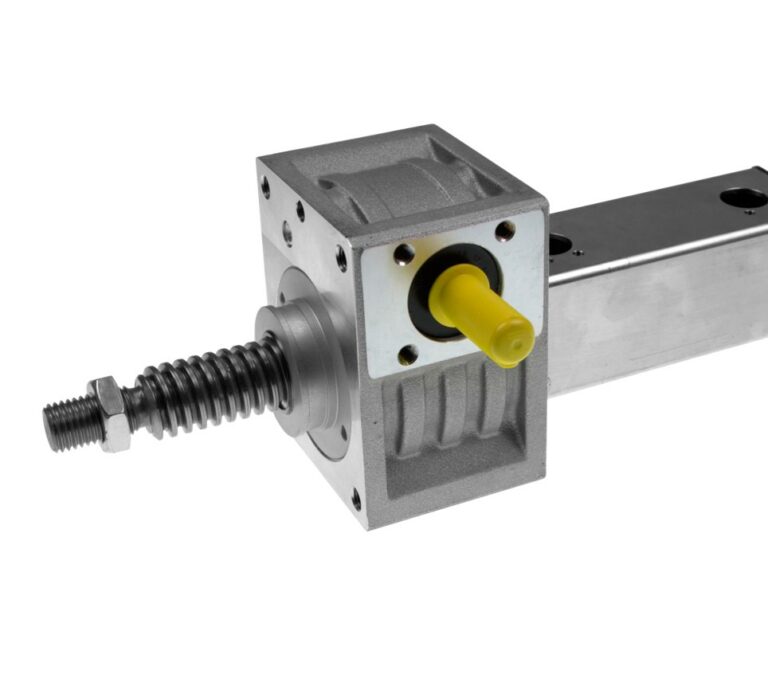

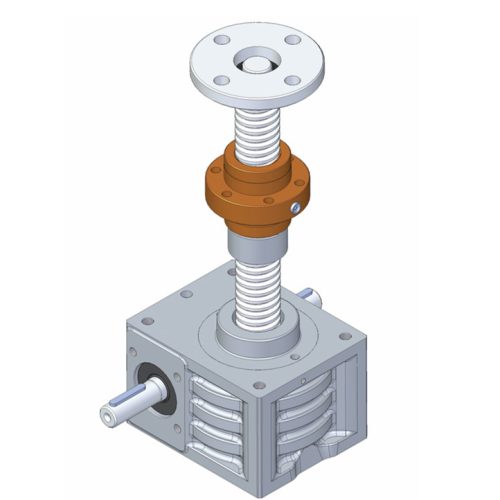

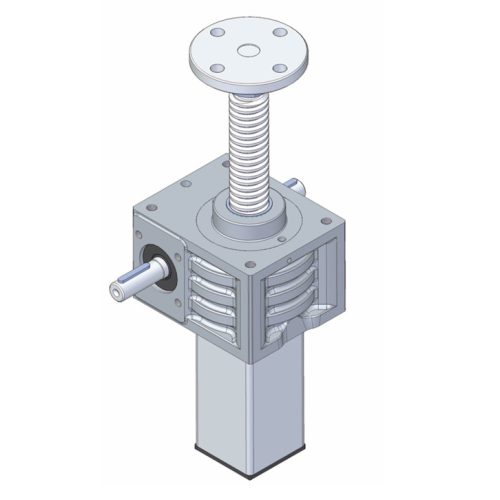

Worm gear screw jacks from Technische Antriebselemente can be driven by external electric drives or manual rotary movements and can be used as linear motion drives. Our worm gear screw jacks can move loads between 2kN and 100kN as standard. With our worm gear screw jacks, we differentiate between screw jacks with a rotating spindle, in which a nut performs the linear movement, and worm gear screw jacks with a stationary shaft. In this variant, a nut installed in the gearbox drives the spindle linearly.

As standard, our worm gear screw jacks can handle loads between 2kN and 100kN.

Please note: The corresponding contact form is located under our TSE configurator. You will find this if you scroll down to the bottom of the configurator.

Please use your desktop for the configurator if possible.

With the help of our TSE configurator, you can find your individual solution for your demanding project in just a few steps.

You can reach us easily via the contact form, e-mail, telephone or chat window.

We create a customized offer tailored to your needs.

Worm gear screw jacks, available in manual and motorized versions, are essential for various industrial applications in mechanical engineering and drive technology. They combine powerful electric motors with precise worm gearboxes to guarantee maximum efficiency and reliability. They are perfect for linear motion in a wide range of industrial applications. Our rotary worm gear screw jacks are particularly suitable for applications that require higher speeds or longer stroke lengths. They are ideal when the screw rotates and the nut remains stationary, making them an excellent choice for dynamic and fast motion sequences. In contrast, our stationary screw jacks are perfect for situations where precision and holding loads in a fixed position are required. With a stationary screw and a moving nut, these gearboxes enable precise positioning and are particularly useful in applications where the load is guided along the screw.

Discover the flexibility and performance of our worm gear screw jacks and how they can meet your requirements in various industries and applications. Contact our technical sales department for a non-binding offer.

Technical drive elements take your projects to new heights of precision and power transmission. Our worm gear screw jacks, tailored to your specific requirements, combine flexibility with performance. Whether for linear movements or load handling, we work with you to develop the right solution – from the initial idea through to implementation. You can rely on our expertise in drive technology for your demanding applications.

Our worm gear screw jacks are used in every industry where precision in linear movements is crucial. Our many years of experience and cross-industry expertise enable us to develop and supply the right solution for every technical challenge.

"The worm gear screw jacks are exactly what we need for our heavy loads. They offer a high load capacity and run absolutely reliably, which makes our production processes more efficient and safer. Very happy with this choice!"

"Thanks to the worm gear screw jacks, we can carry out precise lifting movements with a high degree of stability. The robust design and easy maintenance have noticeably improved our processes. An indispensable product for our requirements!"

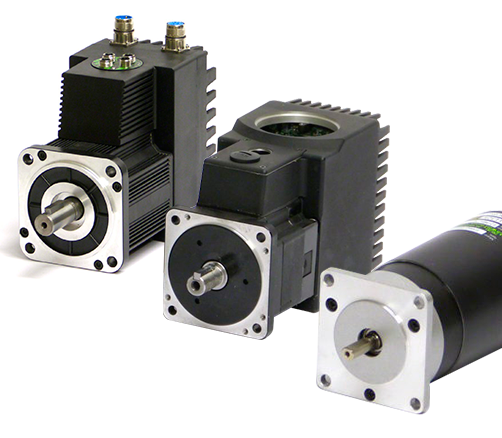

Expand the functionality of your worm gear screw jacks with our specially selected components that fit seamlessly into any drive system. With bellows couplings, standard motors, servomotors and trapezoidal lead screws, we offer solutions that are specifically designed to optimize and improve your drive performance.

A worm gear screw jack is a mechanical device that converts a rotary motion into a linear motion. It is commonly used in the automation, manufacturing and construction industries to precisely lift, lower or position loads. Screw jacks are available in various designs, including manual and motorized models, to meet different requirements.

Rotating worm gear screw jacks, in which the spindle rotates, are ideal for fast or dynamic movements. Stationary worm gear screw jacks with a fixed spindle and moving nut, on the other hand, are suitable for precise positioning tasks. The choice depends on the type of movement and the requirements of your application: speed and dynamics for rotating gearboxes, precision and stability for stationary models.

A manual screw drive is operated by human power, typically via a hand crank or handwheel. This type of actuator is used in applications where electric or automated systems are not practical or necessary, such as simple lifting devices or in environments where electricity is not available or desirable. Motorized screw jacks offer greater efficiency and ease of use, especially for tasks that require repetitive or continuous motion. They are ideal for applications where precise control, higher lifting speeds or lifting heavy loads are required. Motorized gearboxes reduce physical strain on the operator and allow for more accurate and consistent performance.

Screw jacks use a lead screw to generate linear motion and are particularly suitable for applications that require precise control of movement. Unlike other screw jacks, such as hydraulic or pneumatic systems, they offer high positional accuracy and are ideal for fine-tuned movements required in precision manufacturing or laboratory automation. They are also less prone to leakage and can be used in cleaner environments.

Stay up to date: Product solutions & company news straight to your inbox!

Legal Information

© 2025 | Technische Antriebselemente GmbH | All Rights Reserved.